- Pickling Paste

- Cleanwelds

- Competition

We want to start out by saying that our product isn’t better than our competition.

We both do the same thing, with similar science and technology. Thus we feel like we match pretty equally in terms of speed, surface finish and general healthiness.

Because our product is made with readily available electronics and include a full repair manual, we now earn a higher durability rating. Their build quality isn’t bad either, i’m sure, but the lack of repair options or knowledge subtracts few points.

Cost is ~60 USD for paste, ~700 USD for Cleanwelds and ~2000 USD for competition.

Why should we clean? Only for looks?

No, not only.

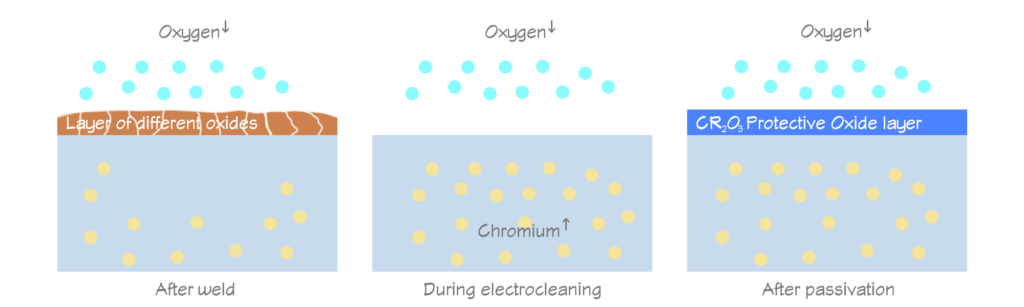

Most important is to re-passivate the metal, to restore its corrosion resistance. Otherwise we would end up with a rusting weld, few weeks later.

While welding or with excessive heat the surface of the metal reacts with oxygen and causes a rough oxide layer that consists of multitute of different chemical elements found in the metal.

It is also full of cracks and other defects as different elements cool and contract at different speeds. The surface layers in the vicinity of the heated zone are also depleted of chromium, which is reguired for to keep the corrosion resistance.

During the cleaning proccess the current pulls the oxide layer away and also raises the chromium in the depleted areas, from the deeper layers.

Now that the surface is clean of contaminants and the chromium levels restored on the surface layer, the oxygen will react to the chromium and forms a thin pure layer of chromium oxide, without any defects such as cracks. This layer will ensure a great corrosion resistanc for years to come.

We would like to make welding equipment almost as prevelant of a tool as a power drill.

So that everybody could afford one, of good quality. And not only afford it but also to be able to maintain and repair it when needed.

Currently it’s saddening to see how the industry grows more and more restrictive by the year. Where the machines cost a lot of money, while you would need to unlock features with an USB stick, no repair or service info, can’t really program the weld profiles without a special guy on a laptop and so on.

If that is something that would interest you as well, then please do help spread the word around and we might actually change it for the better.